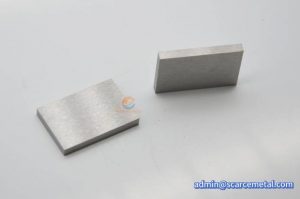

High Purity W Plate

High Purity W Plate Information

Our technical team uses a Powder metallurgy process to produce Tungsten plates, in which high-purity Tungsten powder (99.9% purity or higher) is mixed with a small amount of metallic elements, the blank with a certain strength is prepared by mould pressing or isostatic pressing, and then the blank is pre-sintered at low temperature, liquid phase or solid phase sintering, so that the tungsten particles are combined by diffusion to form a dense plate, and then hot forging, hot rolling and other plastic processing are carried out, finally, according to the needs of customers on the product surface for different treatment. Tungsten sheets used in precision electronic or optical applications must be machined using Electrical discharge machining or Chemical-mechanical planarization to micron tolerances and mirror surfaces.

Advantages

- Super High melting point, excellent high temperature stability, in extremely high temperature environments is not easy to melt, soften or deform, can maintain structural integrity and mechanical properties.

- High density, strong radiation shielding ability, is 2.5 times more than ordinary steel, in a limited space to play the best performance.

- High hardness, excellent wear resistance, suitable for high load, strong friction environment, and long-term use can still maintain surface accuracy.

- Good electrical and thermal conductivity can effectively conduct current and heat dissipation.

- Excellent chemical stability and corrosion resistance, on the molten metal, also has good heat resistance.

Application

Tungsten Plate, with its excellent physical and chemical properties, can be widely used as common mechanical molds, heating elements for high-temperature furnaces, corrosion-resistant components in the chemical industry, heat dissipation substrates for electronics, medical shielding materials, and structural components for nuclear reactors. Aerospace key components (such as rocket nozzles and thermal protection layers for spacecraft), precision electronic components (such as tungsten target materials for semiconductor evaporation), and high-end scientific research equipment components, etc., can ensure that each device operates within the normal working temperature range, guaranteeing their processing efficiency and service life.

High Purity W Plate Parameter

|

Grade |

W1/YG8/WNiFe |

|

Purity |

99.0%~99.95% |

|

Size |

(50-1000)mm×(50-450)mm |

|

Thickness |

0.5 – 100mm |

|

Density |

≤19.3g/cm3 |

|

Tensile Strength |

≥1800-2600MPa |

|

Electrical conductivity |

≥30% IACS |

|

Surface |

Alkaline cleaning, Polished, Grinding |

|

Certification |

ISO 9001 |

High Purity W Plate Picture

Product Qualification