MoW Alloy

MoW Alloy

W-Mo Alloy The service temperature of tungsten and molybdenum alloy is higher than that of molybdenum or molybdenum alloy. In the furnace of high melting point refractory ceramic fiber, if tungsten-molybdenum alloy is used as electrode, nozzle and thimble, its service life is much longer than pure molybdenum products. Commonly used tungsten-molybdenum alloy compositions are: Mo-30W, Mo-50W and Mo-85W. Tungsten-molybdenum alloy is a transition alloy between molybdenum and tungsten. Therefore, the alloy can be used in a wide temperature range between molybdenum and tungsten.

Specification Of W-Mo Alloy

|

Material |

Tungsten Molybdenum Alloy , W-Mo Alloy |

|

Composition |

W30Mo70 or W50Mo50 |

|

Shape |

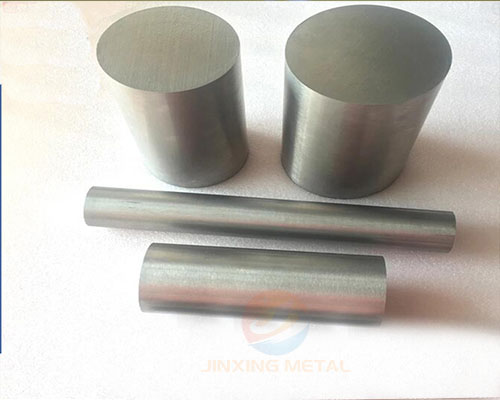

Sheet, Plate,rod,bar,crucible or customized shape |

|

Finish |

Chemical cleaned, ground, |

|

Production method |

Powder Metallurgy |

Molybdenum alloy MoW, through the formation of a solid solution with tungsten (nominal composition by mass percentage: Mo 70%, W 30%, alloy composition content ± 2%), the recrystallization temperature is higher than that of molybdenum (up to 1200 ℃, the deformation ratio is 90% ), high temperature resistance, corrosion resistance, creep resistance (high temperature creep).

Rolled materials made of MoW alloys are used to make parts for high-temperature furnaces, electrodes for power semiconductors, and other applications.

MoW alloy Picture: